The Digital Twin concept is a virtual representation that serves as the real-time digital counterpart of a physical object or process. The concept took flight with industry 4.0. It is a digital, virtual and geospatial representation that serves as the real-time digital counterpart of a physical object or process, thereby increasing efficiency, quality or security of a process.

Through GIS technology, applications can be developed that allow for a graphic representation that is georeferenced to show a physical reality and the digital world linking it to processes.

It can incorporate real-time data that is gathered through sensors and predicts, virtually, what is going to occur.

By way of maps, aerial photos and 3D models that are monitored in order to analyse different situations, performance and efficiency is improved. It comes up with optimal solutions, allowing one to anticipate the detection of any anomaly, in order to solve an issue quickly, permitting cost savings and optimized processes.

In the last few years, GIS technology has become more popular and has been adapted to mobile applications that allow for reading, editing and spatial data storage, as well as for exhaustive and deep data analysis and traceability of processes.

Digital Twin applications

- Automation of management processes; integration with reading systems and data processing.

- Increase in energy efficiency for buildings and production processes.

- Increase in efficiency, quality and security in resource management, maintenance and operations.

Experience

CIC Consulting Informático is a solid company, with a great deal of experience with GIS technologies and other Digital Twin technologies. We are able to provide you with multiple solutions, in order to simplify the management of your company.. We have experience in the utility and other sectors, at the national and international level.

Our experience in these technologies spans over 15 years. Through the tools that we provide, we are able to build an represent a reality of your resources, uniting the real and digital worlds, permitting a better decision making process in the following sectors:

- Maintenance

- Energy efficiency

- Real time analysis

- Simulations

- Etc…

The solutions we provide are customized for each customer. We have over a dozen success stories, with some of the most important companies in the Spanish utility sector and some public administrations.

Advantages in investing in these technologies

There are more and more companies investing in these technologies, mainly because they produce improvements in critical processes in the short term. Add to this cost reductions, shorter work cycle times, work safety, increased efficiency, as well as integration of resources and their maintenance with other cooperative systems.

CIC develops Digital Twin solutions, BIM and resource management models

Through the construction of a BIM (Building Information Modelling) model, one can manage intelligent buildings and critical installations, like substations, petrochemical installations, etc… and for the automation of energy efficiency processes and resource maintenance.

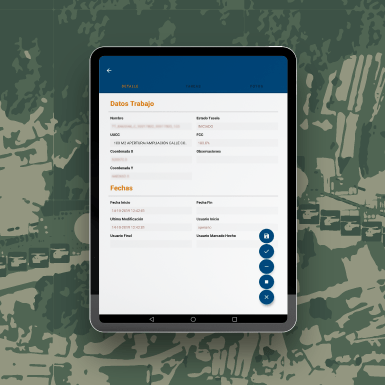

In the resource management and maintenance area, once a resource is modelled, a link is carried out with the information sensors and inventory provide. From that moment on, field work can be managed, alarms and other events too, this way the maintenance process can be traced.

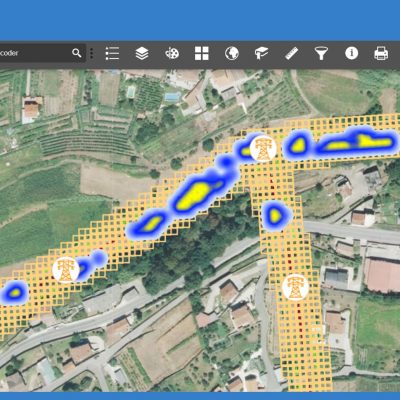

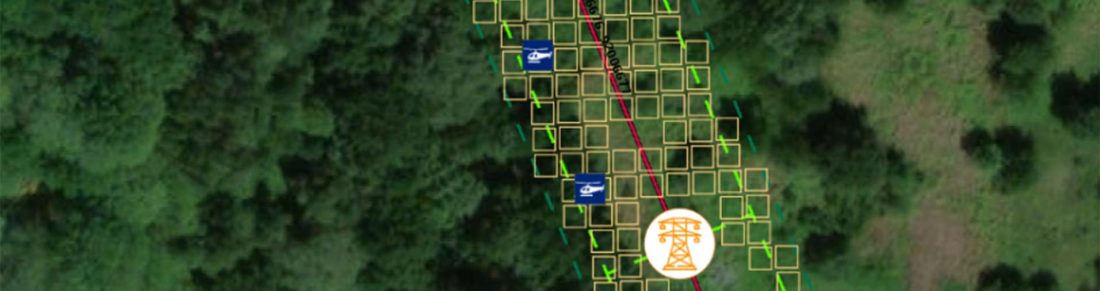

As a practical case, for the data obtained from LiDAR photos and their geoprocessing, through maps and 3D representations, we can see what resources need work: Types of vegetation, distances and other factors such as infrastructures or fire hazards; we consolidate, correlate and identify each element on a cartographic base with GIS tooling. Once the information is consolidated, a maintenance plan is created, based on different algorithms and forms of work that determine the criteria for action.

Once the maintenance plan has been configured and customized, we obtain a maintenance plan where the user has tools to establish the necessary criteria to apply on its resources; critical distances, violations, defects, different types of infrastructures, fire hazards, etc… Always maintaining flexibility, in real time, so that the results can be adjusted to the incurred costs of the work.

For the management of a plan, the system provides a powerful modelling tool for the assumable risk parameters, conditions, budgets, etc… Regarding the configuration, the system carries out a maintenance simulation plan to be reviewed. In case it is deemed unsatisfactory, it can be revised, reconfigured or done over and compared to a new plan.

Once the plan is approved, the work orders will be sent out for their implementation. This can be done through a centralized work planner, or directly by sending out orders through a mobile device, so as to have traceability at all times in the field and in real time.

Once the field work has been finished, the system will update the information, to what degree the maintenance plan has advanced, the costs, as well as a follow up review obtained through satellite images. These solutions allow for improved efficiency and optimization of costs of the maintenance work performed in the field, early detection of any anomalies of work generation in the field, allowing for short term costs savings.