At CIC we have developed a solution for utility companies in their felling and pruning activities. We have devised a solution from the production of a plan, to the actual planning and execution of that plan. This system is already in place with numerous utility companies in the electric sector. However, it can be applied to any industry where felling and pruning is required: Railways, Oil and Gas operators, Forestry, etc…

Once we have data from LiDAR flights, the system is capable of carrying out computer simulations of maintenance plans, business standards, the work that has to be done and the cost of each job. In the creation of each job, different criteria can be applied; optimization, costs, short or medium work.

This is a bespoke solution for each job. Two highly successful cases, with two very relevant Spanish utility companies, will be discussed later.

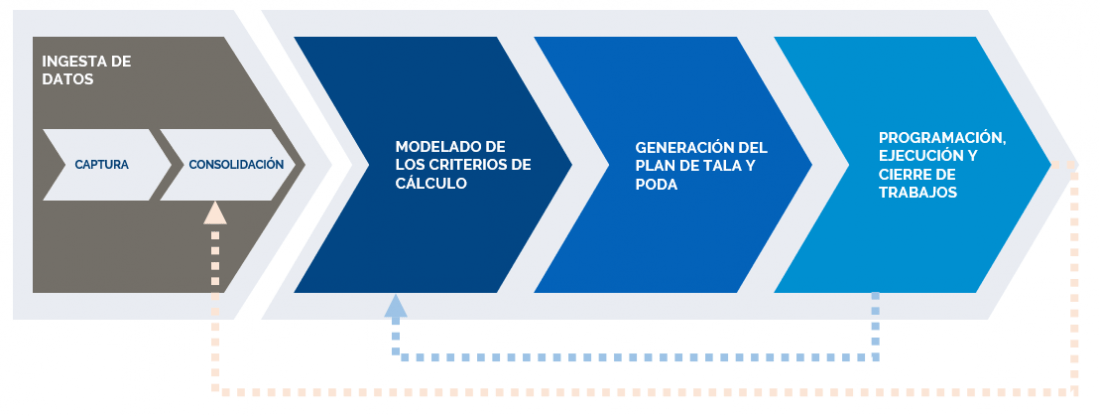

Process for the management of felling and pruning

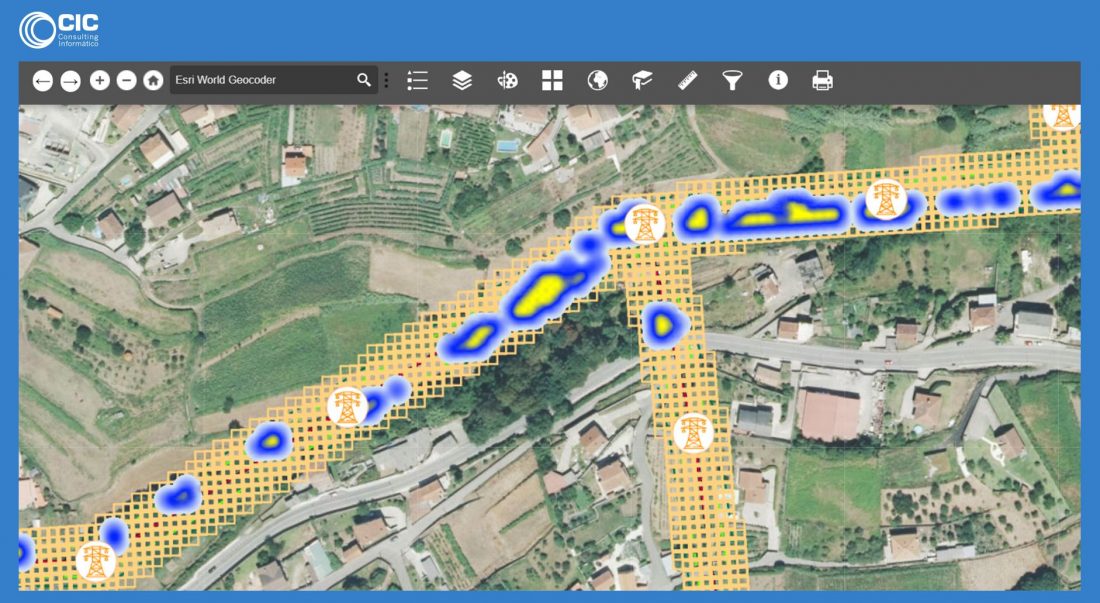

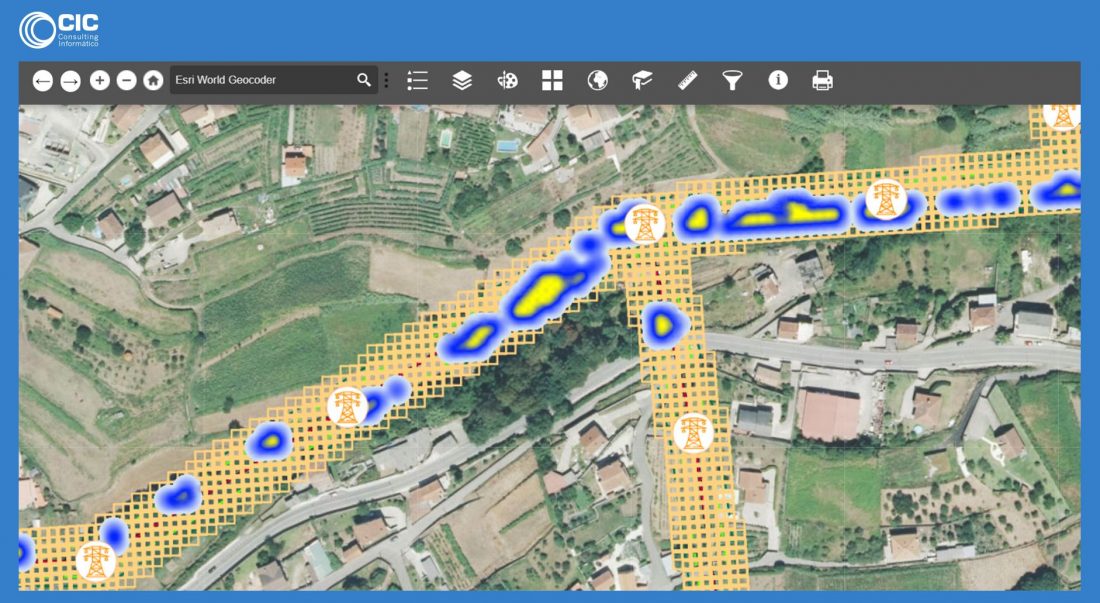

The system works, as mentioned earlier, with LiDAR (Light Detection and Ranging or Laser Imaging) flights. This information is consolidated on a map using one of the available GIS softwares on the market (ESRI, Hexagon, OpenMaps, etc…)

The information is then correlated with the company’s inventory of assets, identifying each asset which has to be reviewed. Once the information is consolidated, the streets or limits defined, a maintenance plan is prepared

For the preparation of the plan, the system provides a powerful modeling tool for the risk parameters of the job at hand, affectations, budget, etc… based upon a configuration, the system carries out a simulation of the maintenance plan for review. If deemed satisfactory, the person responsible will approve it and send the work orders based on the plan, or change the configuration and make another simulation for comparison.

When the plan will be approved, the work orders will be sent out. This can be done through a centralized work planner, or directly by sending work orders to those who will carry them out.

Once the work has concluded, the system will update the information of forest mass, as well as the degree to which the maintenance plan has advanced and the costs that it has incurred.

Detailing the felling and pruning management process

Data intake

The data collection and input in the system is done in four steps:

- Flight overview of electrical grid or network to capture LiDAR images.

- Geoprocessing the images through a raster analysis to obtain the resources and establish work areas.

- Correlation of detected assets with the assets inventory that the company has. Correlation of the positions, regulations, year, etc…

- Publication of map services and incorporation of processed data in the pruning and felling maintenance system.

Customizing

For each implementation, there are various options that the calculation engine and algorithms take into account:

- Work organization

- Scenario selection: Graphically on GIS, per line, per organizational unit, etc…

- Per openings, fragments or tesserae

- Workflow:

- possibility of prior field inspection

- integration with an economic manager (i.e. SAP)

- integration with a work dispatcher (i.e. FIELDEAS)

- Functional criteria

- Regulatory inspections

- Adequacy report. From integration of an external system, or observations from felling and pruning field personnel

- Submission of permits. The system allows you to register documentation, from restricted areas to private land and see those documents on a mobile device through an APP.

- Calculation base: Risk matrix versus periodic growth

- Infrastructure risk. A coefficient is applied according to the criteria of each distribution line

- Fire hazard. Coefficient for each line according to the level of risk (high, medium or low)

- Environmental risks: For each vegetation species the LiDAR flights detect, a coefficient is applied on the risks (trees falling, fire, stability, etc…)

- Proximity criteria

- Distance from vegetation base

- Distance from tree height

- Minimum distance required

- Optimization criteria

- Possibility of incorporating more work to amortize costs.

- Vegetation growth

- Cost of the operation

- Constructive units. Base price for the work: weeding, pruning, felling, etc…

- K supplier. Declared coefficient for each contractor to apply in the base rates.

Results

To create a maintenance plan, one has to establish some business rules that will determine the work that is sought:

After the configuration of the maintenance plan, and once it is customized, you obtain:

The maintenance plan

- Preliminary inspection work

- Total risk coverage

- Detailed cost plan. Relation 1:1 work ratio

- Work orders. One work order for every line

- List of compartments. For each work order, a list of compartments that has to be worked on

- List of fragment or tesserae where work has to be done

- Pruning and felling mobility work

Mobility

Once the system closes down the maintenance plan, felling and pruning orders to the field can be sent, with the correction of defects, to carry out the operation. A mobility application is used, able to work off-line, where each work order is registered in detail; location, number of workers, due dates, etc…

As the field work gets done, progress on the maintenance plan is updated on the application.