Our solutions boost your industrial digital transformation and increase the efficiency of the value chain and your competitiveness, as well as, speeding up the transition towards “intelligent industry”.

The time for industrial manufacturing has come. We possess the best software solutions for you to face the digital industrial revolution or Industry 4.0.

We develop IT solutions for Industry 4.0 and manufacturing

Put your business on the side of developing technological platforms and new operational models which will allow your products and services to be connected and that integrate your client´s operations.

- Quality control for industrial production

Quality control for any finished product (manufactured, produced… any industrial sector). With the ability to block part of the production process (block, adjust, element maintenance) to avoid any faulty product.

- Streamlining and managing warehouse maintenance

Streamlined entry and exit control processes for products in warehouses, allowing for regularisations and helping in warehouse organisation.

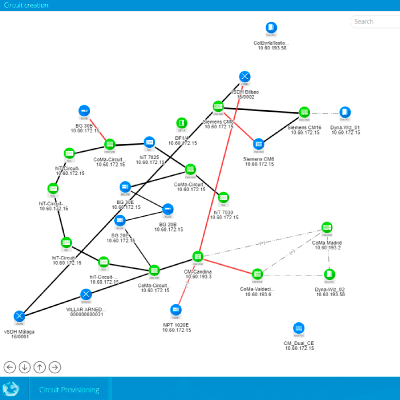

GIS are systems created to capture, store, manipulate, analyse, manage, and present spatial or geographic data. GIS are tools that enable users to generate interactive queries, analyse spatial information, edit data on maps and report the results of all these operations.

- Operational Intelligence, collect and analyse data at the plant.

Thanks to IDboxRT´s capacity for integration with the most often used signals (water temperature, pressure in machines, degree of humidity…) we can carry out different operations. Monitoring and supervising processes, signal integration from whatever source of information, processing, calculating and storing new signals, all used as a tool in the decision making process.

IDboxRT supplies information that allows a manager to optimise, distribute and be more energy efficient.

- Customer Relationship Management (CRM) supported by documents management

More Services and Solutions for Industry

We have years of experience in the Digital Transformation of the automotive, metals, chemical, retail, tourism and Oil&Gas Industries.

With Industry 4.0, companies want the connectivity tools that allow them to have data about the levels of production, availability of inventory and capacity, quality levels, order status, suppliers, etc.

Your workforce will be better prepared and connected to carry out their work more efficiently. Controlling information will increase productivity and improve quality in all your production processes.

- Data monitoring

- Planning and optimising resources

- Predictive maintenance: anticipating problems

- Services management and (Field Services Management)

- Adapted processes to different service models

- SAT, OCA, Field Marketing, commercial strength

- Energy efficiency management

- B2C Processes – Business-to-Consumer

- Industrial Security Solutions