Green hydrogen has become a very promising alternative in the fight against climate change and the transition to a low-carbon economy. In this article we will explore what green hydrogen is, its advantages and its potentially key role in the energy revolution.

What Exactly is Green Hydrogen?

Green hydrogen is the hydrogen produced from renewable sources, such as wind or solar energy, through a process called alkaline electrolysis. This technology allows hydrogen to be separated from water, thus creating a clean, carbon-free fuel.

Advantages of Green Hydrogen

- Lower Emissions: Green hydrogen produces no carbon emissions during its use, making it a clean alternative to fossil fuels.

- Efficient storage and transport: It can be easily stored and transported, making it a flexible solution for supplying energy to a variety of sectors, including transportation and industry.

- Diverse applications: It can be used as a fuel for fuel cell vehicles, as a raw material in the chemical industry and as a source of energy for power generation

How can we use Green Hydrogen?

- Sustainable transportation: Green hydrogen can power fuel cell vehicles, offering an emission-free system for the transportation sector.

- Industrial sector: Green hydrogen can be used as a raw material in the production of ammonia, methanol and other chemicals. Consequently it would reduce our dependence on fossil fuels.

- Energy storage: Green hydrogen can be used as a form of large-scale energy storage, allowing renewable energy to be harnessed when it is available and used at times of high demand.

Production challenges and advances

- Costs: Although hydrogen production costs are decreasing, it is still early and relatively expensive to be adopted massively.

- Infrastructure: Appropriate facilities are still required for the production, distribution and utilization of green hydrogen on a large scale, which is still one of the principal challenges that has to be addressed.

- Research and development: Advances in electrolysis and green hydrogen storage technologies continue, which will eventually boost their viability and market competitiveness.

- Finding ways to store the gas is one of the challenges that is faced. A safer means other than direct compression has to be adopted as it is very flammable. An option that is available at the moment is to convert it into ammonia (NH3), and once it has arrived at its destination, reconvert it back to hydrogen (H2).

Technology and optimization in the production of green hydrogen

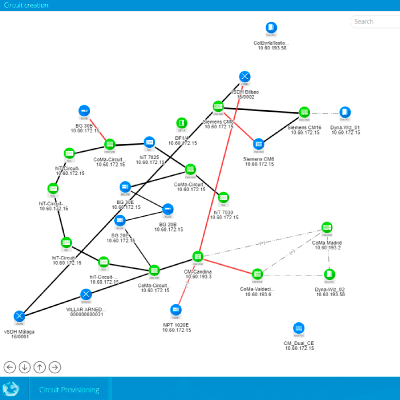

Efficient production of green hydrogen requires advanced technological know-how that allows monitoring, control and optimization of the processes. The solution is the implementation of specialized software platforms, which result in a more efficient use of energy.

- Real-time monitoring: Through the use of sensors and data acquisition systems, it is possible to obtain realtime information on the key parameters of the electrolysis and ammonia synthesis processes. This makes it possible to detect any possible deviations and take early preventive or corrective actions.

- Control and automation: Technology plays a crucial role in the control and automation of the equipment and systems involved in the production of green hydrogen and ammonia. State-of-the-art control algorithms and systems allow for precise adjustment of operating conditions guaranteeing the efficiency and safety of the process.

- Optimization of energy efficiency: Through data analysis and process modeling, software platforms can identify areas for improvement and propose strategies to optimize all processes involved, especially energy efficiency. Within the scope of energy efficiency, energy optimization is paramount in order to perform the electrolysis, as well as the optimization of the cycles and heat distribution in the ammonia synthesis process.

- Predictive maintenance: Technology plays a key role in the system´s adjusted predictive maintenance. Technology allows for the system to anticipate possible failures or problems with the equipment. Through the analysis of historical data and the implementation of artificial intelligence algorithms, it is possible to predict and plan maintenance activities, minimizing downtime and maximizing the system´s availability.

The use of technology in the fields of monitoring, control and optimization of electrolysis and ammonia synthesis processes ensures more efficient and sustainable production, thus improving the economic and environmental viability of the project.

Conclusion

The use of advanced technology and specialized software platforms are key in green hydrogen production. Through a real-time monitoring process control and automation, optimization of energy efficiency and predictive maintenance, efficient and sustainable energy management can be achieved.